School is back in session and so is Futures+, we can’t wait to see what comes out of this year’s studios and endless all nighters. We look forward to seeing your projects or your fellow classmate’s asleep under their desk! So we are kicking off the year with a project we came across awhile back by a group of students out of the Boston School of Architecture. Screen Wall was a workshop studio exploring digital fabrication in collaboration with Radlab, a rather interesting multidisciplinary design and fabrication consulting firm. The studio explored the field condition of a unit that could act as a ever changing screen element within the space. The playful exploration as the wall not as a static element makes you want to push this project even further. Check it out after the jump!

STUDENT: Aaron Anderson, Asli Baran, Bram Koss,

Pierre Lamboni, Connie Leite, Neil Piatt

SCHOOL: Boston School of Architecture

PROFESSORS:Matthew Tremble – Radlab, Inc

YEAR: 2012

Screen Walls from Radlab Inc on Vimeo.

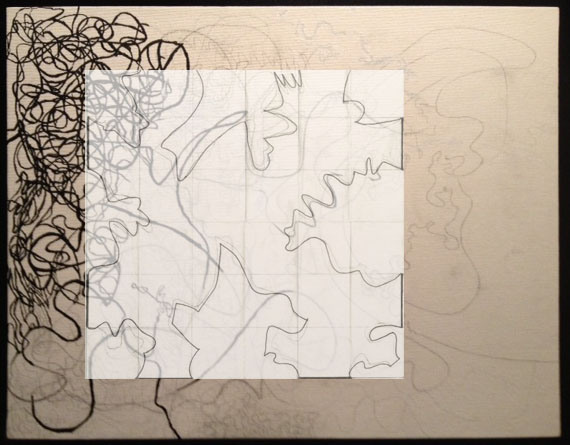

Background //

‘Screen Walls’ is the result of an eight-week workshop through the Boston Architectural College, centered around the design, fabrication, and assembly of an architectural screen wall. Using Radlab’s robotic arm for production, the class focused on the relationship between the unit and the group, and its effect on the perception of continuity.

Scale //

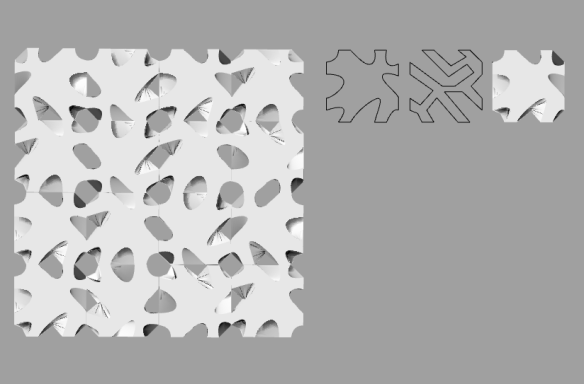

The screen wall is composed of 16 modules, each 2’x2’x6”. The size of the wall is intended to be large enough that its broader architectural implications may be readily evident, and yet small enough that it could be conceived, manufactured, and assembled by a few people, with a small budget, in a short period of time. Students were tasked with designing locally, at the scale of a single module, while adhering to certain global constraints.

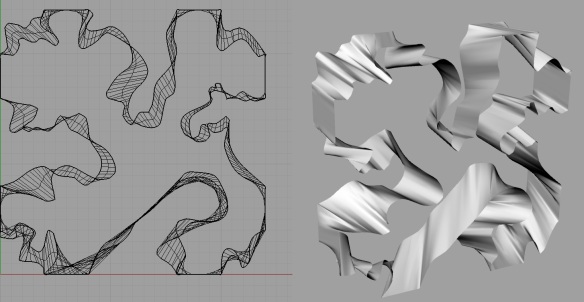

Form //

The geometric properties of each module are products of the following conditions: [1] every 4”x6” ‘connector’ platform distributed about the perimeter must remain uncut, [2] all surfaces must be ruled (through every point on the surface there is a straight line that lies on the surface) or doubly ruled (through every point on the surface there are two distinct lines that lie on the surface), [3] only single sweep passes between any two ‘connector’ nodes are permitted.

Program & Performance //

The screen wall serves as a reconfigurable, space dividing filter. As the nature of its porosity changes with each new composition, so does the manner in which it filters light, views, touch, and sound. Depending on the type of configuration, it may behave more like a column (vertically oriented) or a fence (horizontally oriented). The module’s transportable and formal attributes enable it to be moved, positioned and oriented according to potentially varied surrounding conditions.

Material & Machining //

Expanded Polystyrene (EPS) is lightweight, inexpensive, recyclable, holds its shape well, and is easy to machine. The material is meant to be read both as literal, and as an abstraction, or placeholder, for what could be a variety of materials. For cutting the material, students were introduced to Radlab’s Kuka KR15-2 robotic arm at the beginning of the course, wherein the robot’s dimensional constraints and motion limits were demonstrated and explained.

FUTURES+ Original Submission by Asli Baran